My primary coil is wound on a 15-degree incline, using 1/4" copper refrigeration tubing, just under 50 feet. I constructed six triangular 3/8" thick lexan supports, drilling 1/4" holes every 1/2" along the long edge, then hacksawing and filing the holes into slots that the tubing could be pressed into. Between every six turns I drilled and tapped a 6-32 hole for the thin lexan hold-down strips, secured with nylon screws.

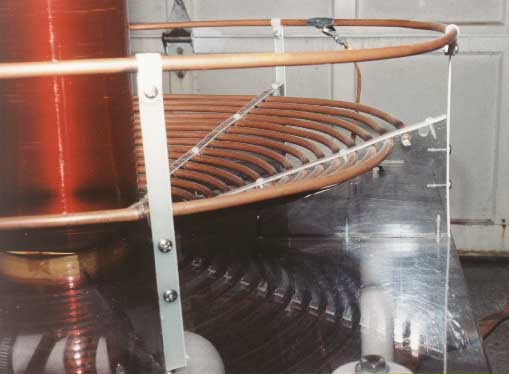

The primary strike rail is also made of 1/4" copper tuning. G10 strips and cable clamps support the rail above the primary supports (lexan strips weren't rigid enough). The rail is about 1 inch short of being a complete circle. You can see the alligator clip connecting the ground to the strike rail. I had to cover it with aluminum tape to smooth out the sharp edges of the clip, which were attracting an arc from the primary (or was it the toroid?).

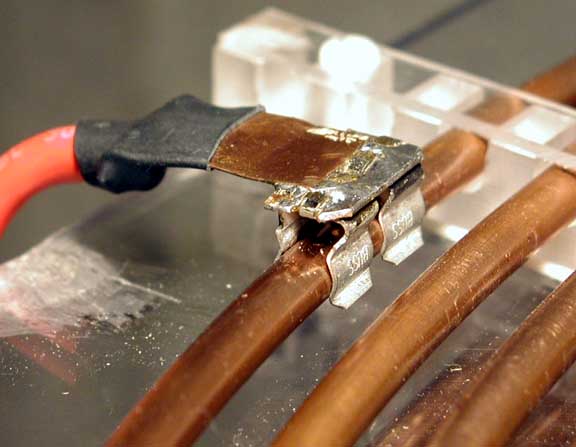

This shows one way to connect the primary tap. I formed two pieces of sheet brass around a 1/4" drill bit, and just screw them to the cable's ring terminal.

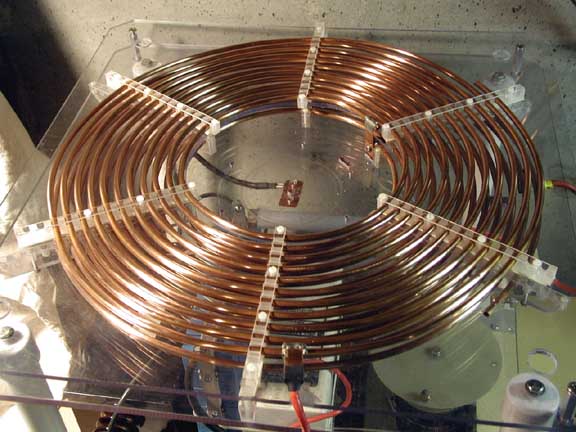

I have since switched from the conical primary to a flat primary to increase the striking distance from the top load, and more recently, to a two-layer flat primary, in order to achieve a higher primary inductance (to tune a comparably higher-inductance secondary) in a reasonable space. The two coils were wound in opposite directions, joined at the center. Originally each coil had 13 turns, but I had problems with arcing from top-outer-turn to bottom-outer-turn. Since I didn't actually need that many turns, I trimmed each coil back to 11 turns. The total inductance of the two coils is 165 uH. Each individually is 46 uH. ID is 8.5, OD is 19. Vertical separation of the two coils is 1.125

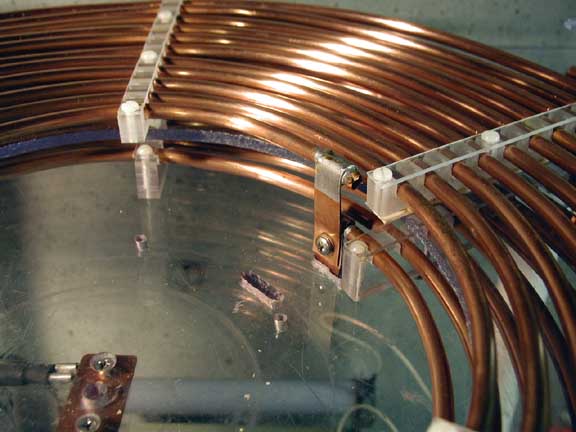

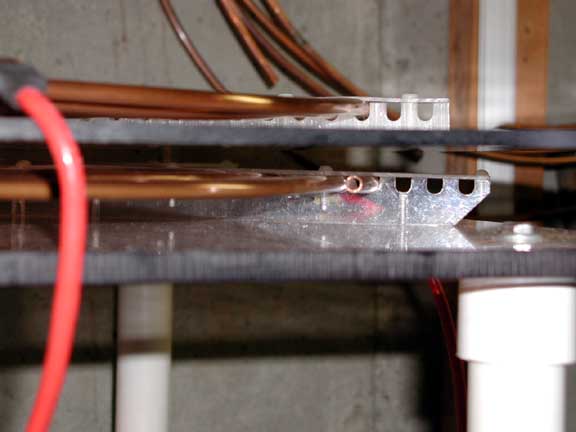

Custom-made Lexan combs space and support the copper tubing, and a 1/16 thick x 3/8 wide Lexan strip holds the tubing in the notches. Nylon screws are threaded into the combs to secure the strips. The lower coils combs are fastened to the 3/8 Lexan lower deck with steel #6 screws going through the deck. But the upper combs had to be secured to the upper ¼ Lexan deck without any holes in the deck, as any holes would invite arcing between the upper and lower coils. Instead I used double-sided foam tape to secure the combs.

Below is another method of connecting the primary tap, using a pair of ¼ fuse holders. The scratches on the Lexan deck are where some surface-tracking arcs occurred before I removed the outermost two turns.