While 'Bigger (sparks) Is Better" has been the guiding axiom behind most of my coiling activities, I've always wanted to build a table-top sized coil that I can just plug and play without breaking my back to move it, set it up, clearing out the garage, disconnecting the garage door openers, etc. There's been nothing preventing me from building such a coil, it's just that working on my big coil has turned out to be a never ending endeavor. Nothing wrong with that, I just needed to get a "round tuit" to start my small coil.

Well, I finally did, and the results are gratifying. To a grounded target, I get continuous 9" streamers, frequent 11" streamers, and most recently, occasional 14" strikes. All much louder than I would have expected!

Specs:

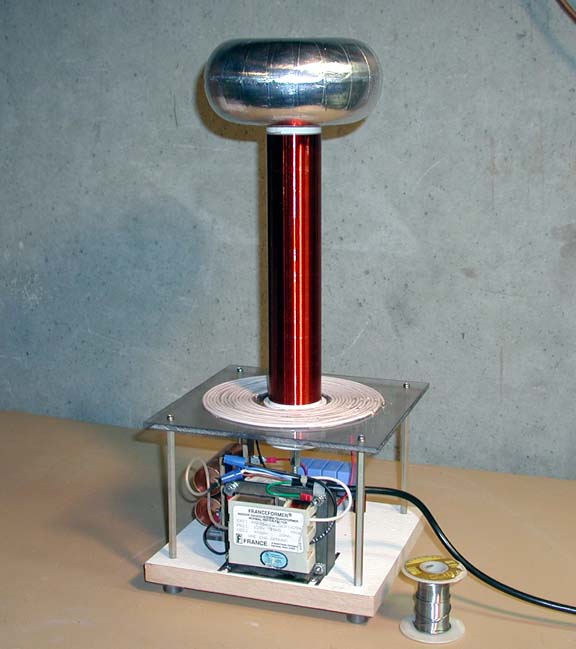

Model A:

Power supply: A 4kV/20mA Franceformer NST. This is an open frame, one side grounded, un-potted unit, which means that the current limiting shunts are easily removed. With unmodified shunts I got 6" streamers. Removing all shunts I got between 8"-9" streamers, though the NST got warm after about 30 seconds. I compromised and put back half of them. With no power factor correction and the half-removed shunts, the NST pulls 1.75Amps @120V from the wall and delivers 38 mA into a short circuit. Interestingly, I initially got only 5" streamers prior to knocking out the shunts, but this was also before I made everything neat and tidy with short interconnect wires. Keep them wires short!

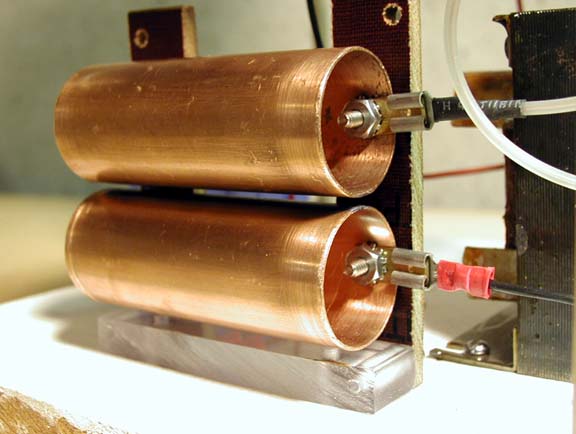

Spark gap: A single static cylinder gap - Two 1 1/8" diameter x 3" long copper pipes, spaced 0.05". Initial testing showed no benefit to adding forced airflow, but I later found a small fan from a microwave oven which fit nicely. While maximum streamer length did not seem to improve, the streamer brightness and loudness did noticeably improve.

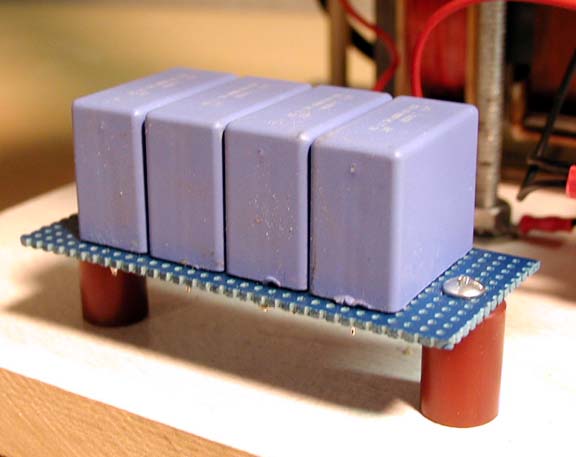

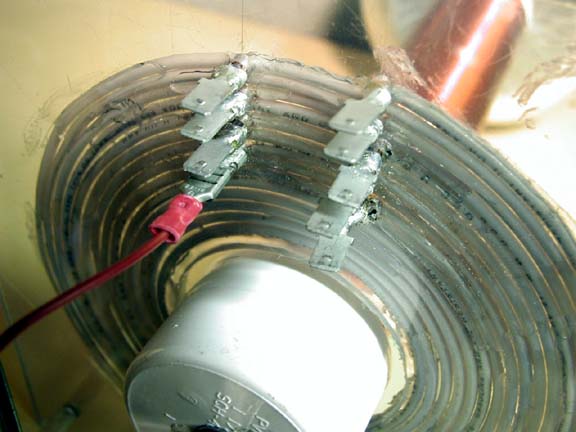

Tank cap, Model A unit: A .012uF/6400VDC MMC cap, made of four .047uF/1600V, BC Components KP/MMKP376 polypropylene caps in series. I found that a significant charge remained on the individual caps after turning off the unit, so I added a 10Meg 1/2W resistor across each one to bleed off residual charges.

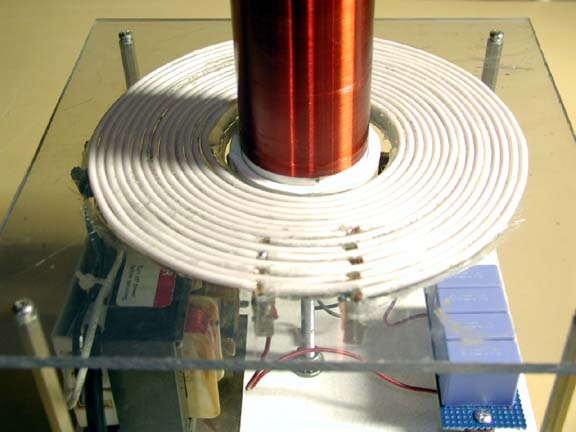

Primary coil: A flat spiral of insulated solid 12AWG wire. I.D. = 2.9", O.D. =6.5". Turns were hot melt glued to the Lexan support plate. Fixed taps at turns 6.5 through 14.5 are terminated (soldered, not crimped) to male Fast-On terminals, for secure but easily changed connections. While compact and functional, this proved to be a very labor-intensive construction technique. Best performance with present top load at tap 7.5.

Secondary coil: 1.9" O.D. PVC pipe, 9.5" winding length (~1100 turns) of #32AWG magnet wire, polyurethane coated. Measured inductance is 10.4 mH. No special form preparation or baking.

Top load: I found a plastic shipping skid cushion used for computer equipment that was the perfect shape. The bottom was flat and the top toroid-shaped. 3" high x 6" diameter. Covered it with the usual aluminum tape. System resonance (operating) is about 500 KHz with this top load.

Protection network: Nothing (yet).

Ground system: Inner primary turn, secondary base, and NST core all connect to 3rd wire AC ground. When using NST's, it's generally not a good idea to connect the secondary base to the inner primary turn, as this would make the secondary "hot" and potentially lethal to touch. But since one side of my NST is grounded, I was able to ground the inner primary connection.

Specs, model B:

Tank cap: A .025uF/8000VDC MMC cap, made of four 0.1uF/2kV Cornell Dubilier (Geek Group) caps, also with 10M bleeder resistors. I tried five in series for .020uF, but saw no difference after retuning.

Primary coil: Removed inner (2?) turns to eliminate strikes to secondary. ID is 3.25", best performance in model B configuration is at tap 6.5.

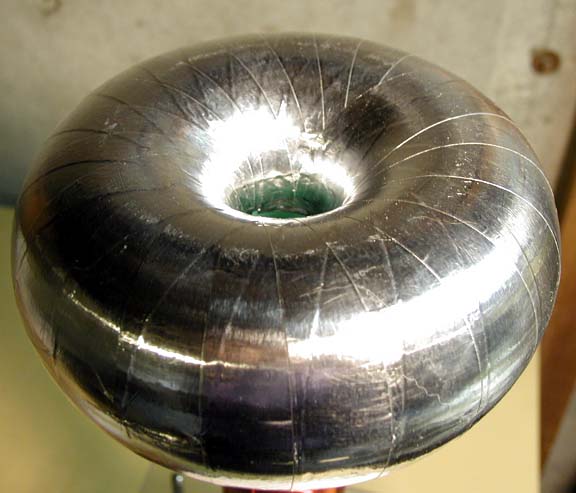

Top load: 3.5" x 10.75" toroid, made from corrugated aluminum duct. With a hastily constructed bare-duct toroid, the corrugations acted as breakout points, resulting in numerous small streamers and poor performance. Covering the duct with aluminum tape did not eliminate the ridges, and I still had multiple streamers. I covered the bare duct with paper mache, using strips of newspaper dipped in a 50% water/Elmer's glue mixture. This did a very nice job in smoothing the corrugations, although it took several iterations of patching the high & low spots. With the glue binder, the surface files nicely with a wood file. After smooth & dry, I covered the toroid with aluminum tape. With the paper mache between the tape strips and the duct, I observed arcing between adjacent tape strips. I added a wood center disk, with a compliant, conductive EMI gasket between the disk and the ID of the toroid. This shorted together all of the tape strips and solved the arcing between the tape strips.

Model A mini coil

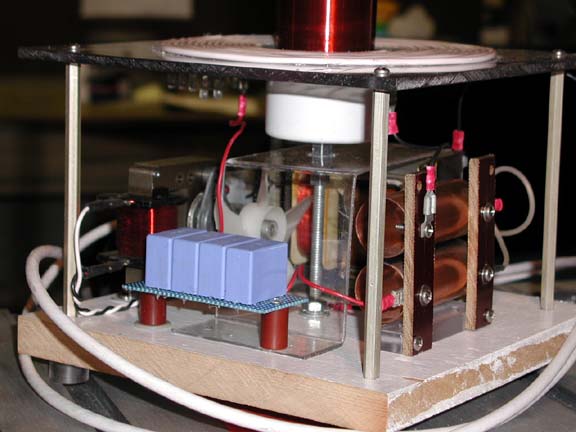

Above shows the fan and a Lexan manifold directing the air through the gap.

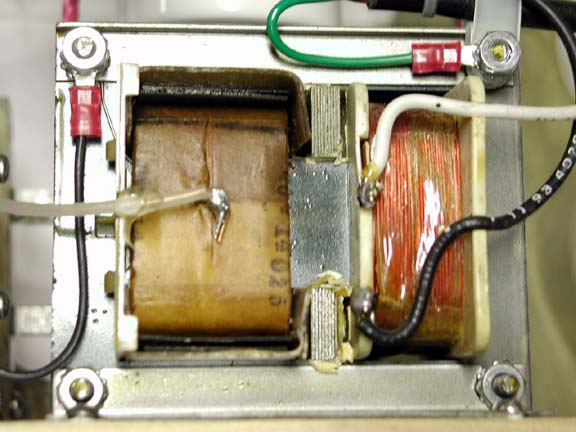

Here is the NST, showing the half-removed shunts (2 places) between the primary

(right) and secondary (left) coils.

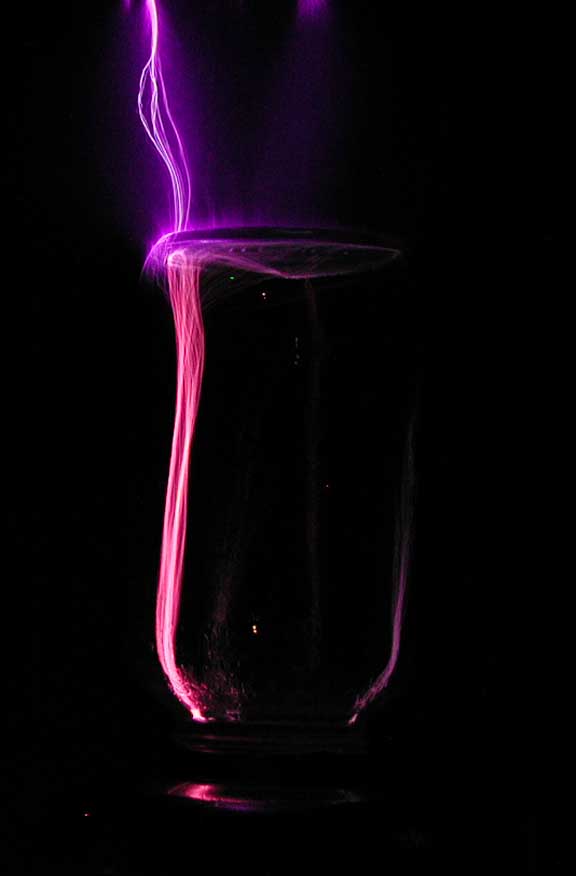

Above is something that would have been very difficult to do with my big

coil. I took a 26 oz. glass pasta sauce jar, put 1/2" of water in it,

boiled for about a minute in a microwave oven, and tightened the cap. This

displaces the air with water vapor, and when it cools, creates a water

vapor-rich partial vacuum

in the jar. I put the jar on top of the toroid, cap-side down, and put a 2

foot-length of threaded rod (anything would do) a couple inches above the top of

the jar to arc to. The result is beautiful! The rarified air and water

vapor created a stunning pink plasma, which gets less pink and

more violet as it cools down.

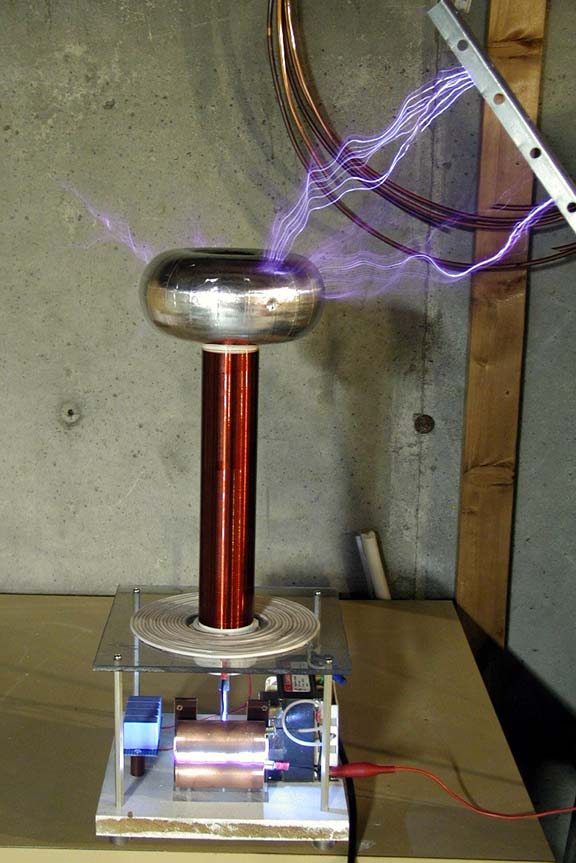

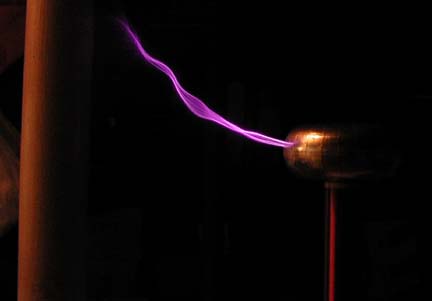

Above shows something that I rarely see on other coils. When there is a

grounded target just out of striking distance, the usually chaotic streamer(s)

will occasionally coalesce into a single, sinuous, un-branching, slowly writhing

streamer, lasting 1-5 seconds at most. The sound generated is more stable

and louder than normal as well. In the photo, there is a basement lally

column 10" away from the toroid, and there will be a brief strike to it

every 30 seconds or so.

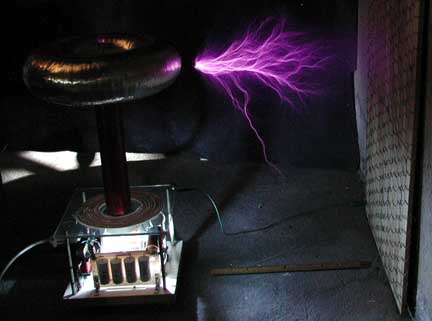

Mini coil, model B

Model B, set up to record a 14" strike

My best spark length from the model B configuration has been 14". There are two very important tricks necessary to extract the longest streamers to a grounded target.

First, the tip of the breakout point on the side of the toroid is critical. It must not be a point, but rather a sphere. A rounded arc of 14 gauge wire was too small, and a 1.75" diameter spherical doorknob was too big. Best results were had with a 1/2" brass sphere.

Second, the strike target is critical. I had been using a basement lally column and a basement foundation wall, but the best I could extract was 12" strikes. I later noticed that using a chicken wire covered faraday cage (of Death) as a target at the RATCBA teslathon, I was able to better my 12" record by 2". And I have since reproduced the results at home, using a small sheet of plywood, covered with chicken wire.